1. Best Powder Coating Oven Equipment Overview

The Best Powder Coating Ovens deliver precise temperature control, energy efficiency, and durability. Premium models feature high-grade heating elements (electric or gas-powered), insulated chambers (ceramic fiber or refractory brick), PID controllers, and convection fans for uniform heat distribution. Top brands like Grieve, Wisconsin Oven, and BlueM prioritize corrosion-resistant interiors, multi-zone temperature settings, and automated conveyor systems for industrial-scale curing.

2. Best Powder Coating Oven Applications

These ovens are essential for automotive (car parts, wheels), aerospace (engine components), furniture (metal fixtures), and appliance manufacturing (refrigerators, ovens). They cure epoxy, polyester, and hybrid powders into durable, weather-resistant finishes. Compact benchtop ovens suit small workshops, while large industrial units handle high-volume production.

3. Best Powder Coating Oven Pricing

Benchtop ovens for DIYers cost 1,500–5,000. Mid-range industrial models (20–50 cubic feet) range from 10,000to50,000. Custom large-scale ovens with conveyor integration exceed $100,000. Energy-efficient gas ovens reduce operational costs by 20–30% compared to electric alternatives.

4. How to Use a Best Powder Coating Oven Correctly

Preheat the oven to the powder manufacturer’s recommended temperature (350–450°F).

Arrange coated parts evenly to ensure airflow and avoid hotspots.

Use thermal sensors to monitor curing consistency.

Ventilate exhaust gases to meet safety regulations.

Allow parts to cool fully before handling or packaging.

5. How to Choose the Best Powder Coating Oven

Prioritize oven size, max temperature (450°F+), and fuel type (gas for cost efficiency, electric for precision). Look for UL/CE certifications, warranties (1–5 years), and energy-saving features like recirculating burners. Read reviews for brands with proven reliability in your industry.

6. Best Powder Coating Oven Safety Tips

Install carbon monoxide detectors for gas ovens.

Wear heat-resistant gloves and goggles during operation.

Ensure proper ventilation to prevent fume buildup.

Regularly inspect gas lines, electrical connections, and insulation.

Train staff on emergency shutdown protocols.

7. Design Rationality of Top Powder Coating Ovens

Advanced designs minimize energy waste with insulated walls and recirculating airflow systems. Modular components allow easy maintenance (e.g., replacing heating coils), while programmable controls reduce human error. Industrial ovens often integrate IoT for remote monitoring and predictive maintenance.

8. Best Powder Coating Oven FAQs

Q1: What is the best oven temperature for automotive coatings?

A: 375–400°F ensures optimal curing for most automotive powder coatings.

Q2: How often should I clean my powder coating oven?

A: Clean filters weekly and inspect burners monthly to prevent efficiency loss.

Q3: Are electric ovens better than gas models?

A: Electric ovens offer precise control, while gas models are cheaper to operate at scale.

Q4: Can I cure UV-resistant powders in standard ovens?

A: Yes, but verify the powder’s curing requirements match your oven’s capabilities.

Q5: Do premium ovens come with extended warranties?

A: Top brands often provide 3–5-year warranties for industrial-grade equipment.

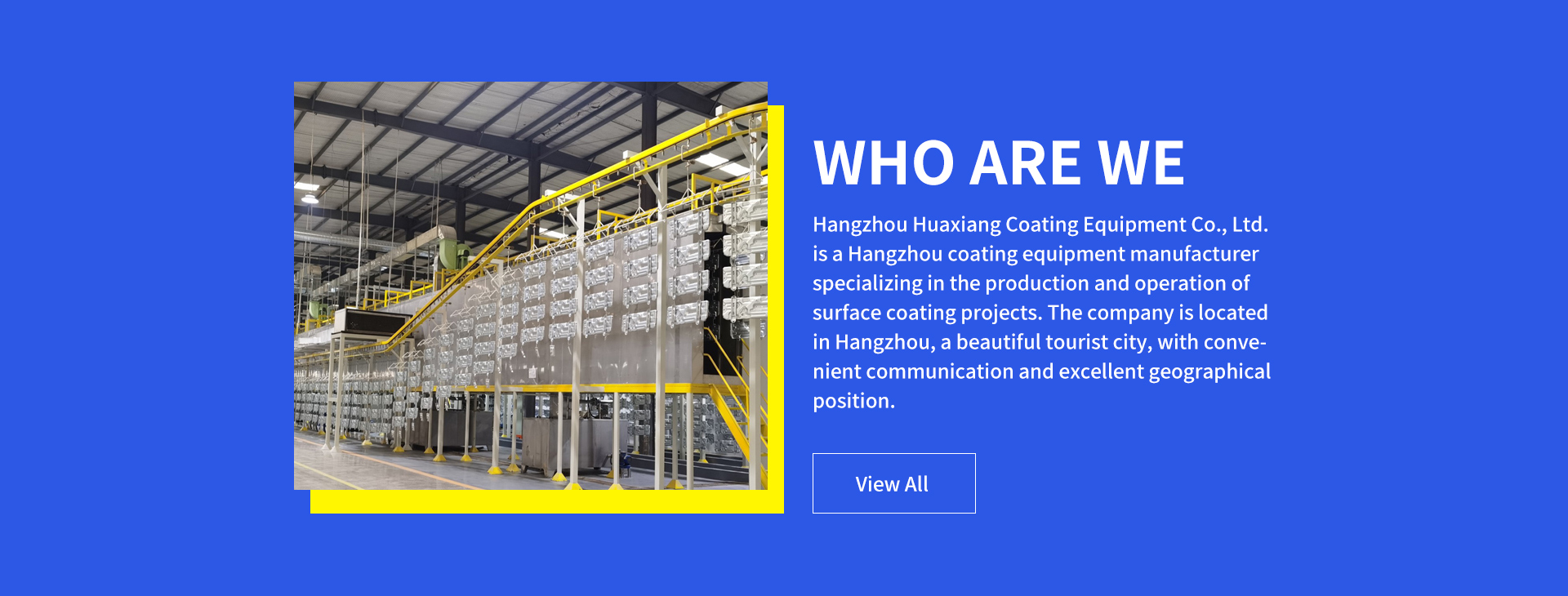

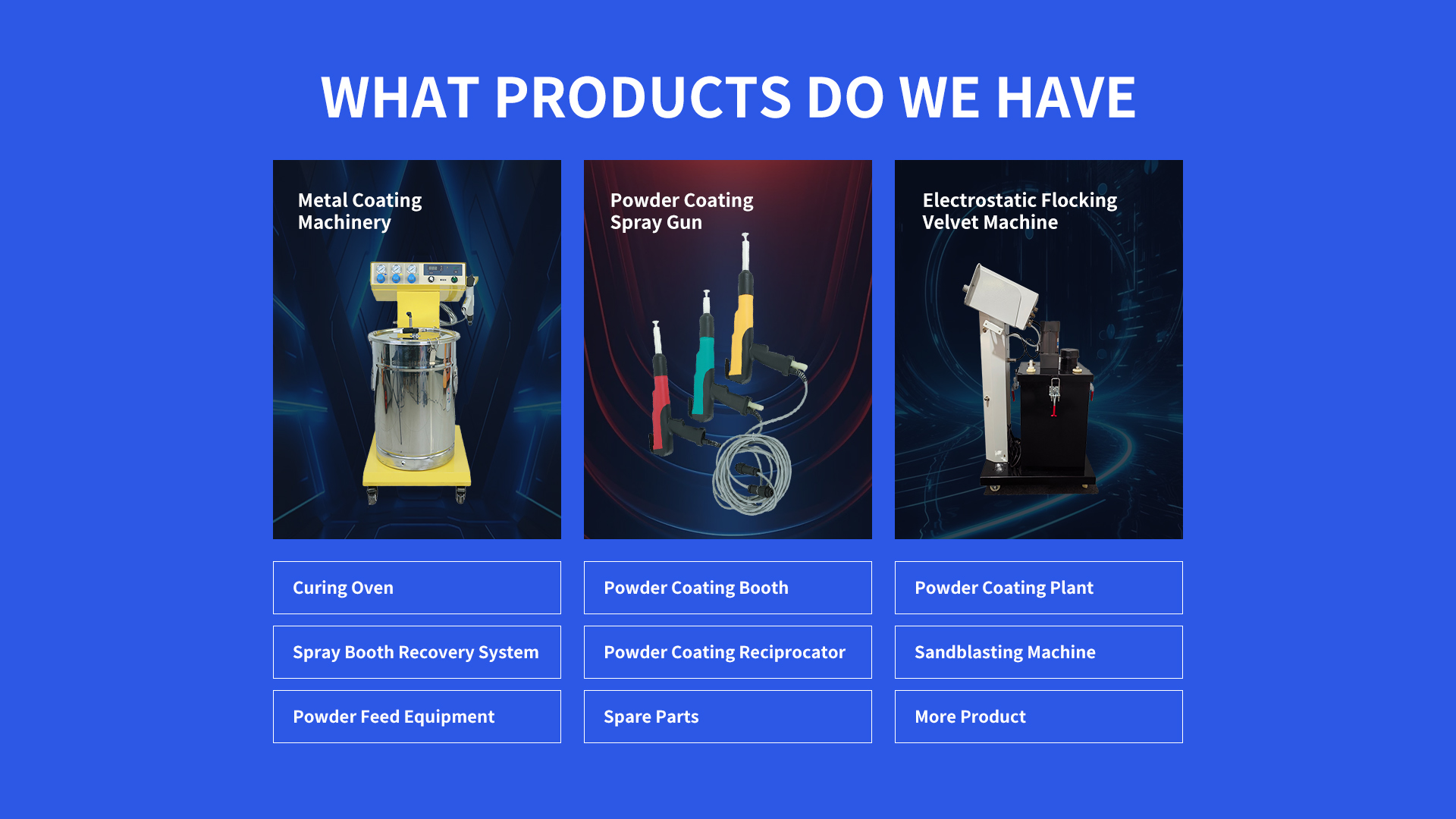

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com